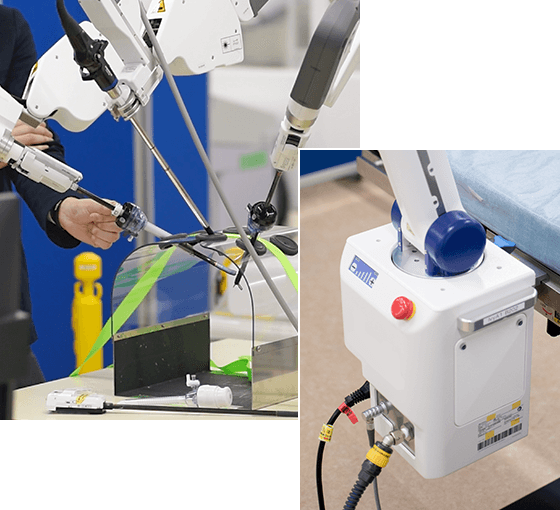

Pneumatics is an excellent technique for replicating soft, smooth movement.

Riverfield develops robots with a focus on minimizing the risk of injuries and accidents, pursuing safety in collaborative work between robots and operators, and providing technology that correctly and accurately reproduce human motion.

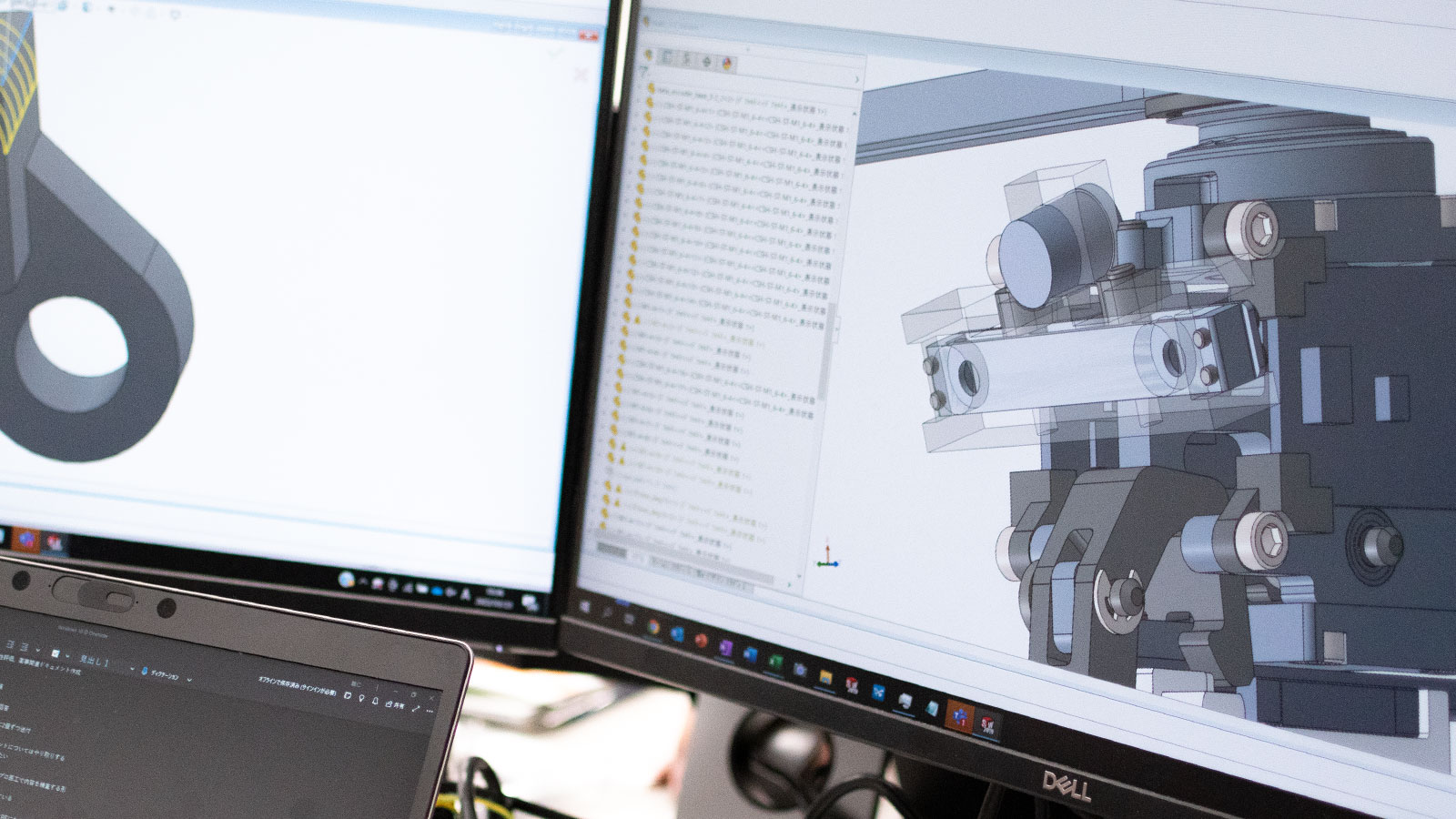

With the cooperation of Japanese companies with a variety of unique technologies, we are developing precision robots that incorporate unique Japanese hardware craftsmanship, a precision manufacturing powerhouse.

Since 2003, Riverfield Inc. has established the world's only technology using pneumatic pressure to drive robotic forceps through R&D led by the Tokyo Institute of Technology.

We have repeated evaluations of prototypes and animal experiments to improve the performance of surgical robots with the cooperation of the surgeons at Tokyo Medical and Dental University.

We conducted various R&D on both the hardware design of precision robots and the software technology to precisely control them.

We have also focused on researching peripheral technologies for safe operation and to deal with various risks. Thus, we have developed surgical robots based on the results of approximately 20 years of our research.